- 10 - 1,200 kW cooling capacity

- Up to 30 % better overall plant efficiency

- Saves costs for electricity and water

- Most energy-efficient way of cooling in concrete production

- Pre-installed in 40-foot container or in two 20-foot containers

- Ammonia as refrigerant

KTI – Plersch

Silo cooling & cold air generation

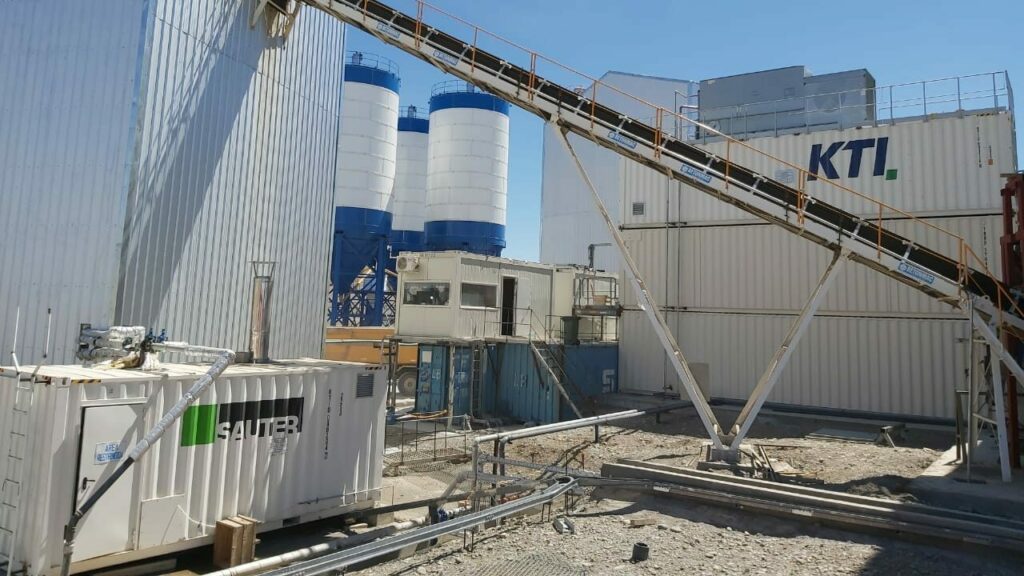

Our customers also want to concrete throughout the summer. For this, they need equipment to cool larger quantities such as gravel and other aggregates. This is done by the KTI CCAP cold air unit. Alternatively, the KTI SAUTER Combimaster can be used to cool the gravel in summer and heat it in winter before processing.

KTI – Plersch

Silo cooling & cold air generation at a glance

KTI – Plersch

Cold Air Plants for Aggregate Cooling

KTI – SAUTER

CombiMaster

- Silo heating and silo cooling

- Hot water and cold water

- 1 container for the whole year

- Compact design

- Hot water and cold water

- 1 container for the whole year

- Compact design

Cold Air Generation & Silo Cooling

Your advantages

With the KTI cold air units the Efficiency of existing systems for concrete cooling can be significantly increased. The use of cold air saves costs for electricity and water, because the implemented technology allows the cold air system to be more efficient works. The use of cold air to lower the temperature of the aggregates before they are fed into the concrete mixer is the most energy-efficient way to cool concrete economically. This can improve overall efficiency by up to 30%.

The KTI SAUTER CombiMaster is a All-In-One System for heating and cooling. It contains a complete refrigeration system for active cooling of water and air. Thus it enables a trouble-free concrete production all year round. In addition, he is highly mobile and space saving due to the container construction.

KTI – Plersch

We are here for you

Your contact to our experts

How would you like to be contacted?