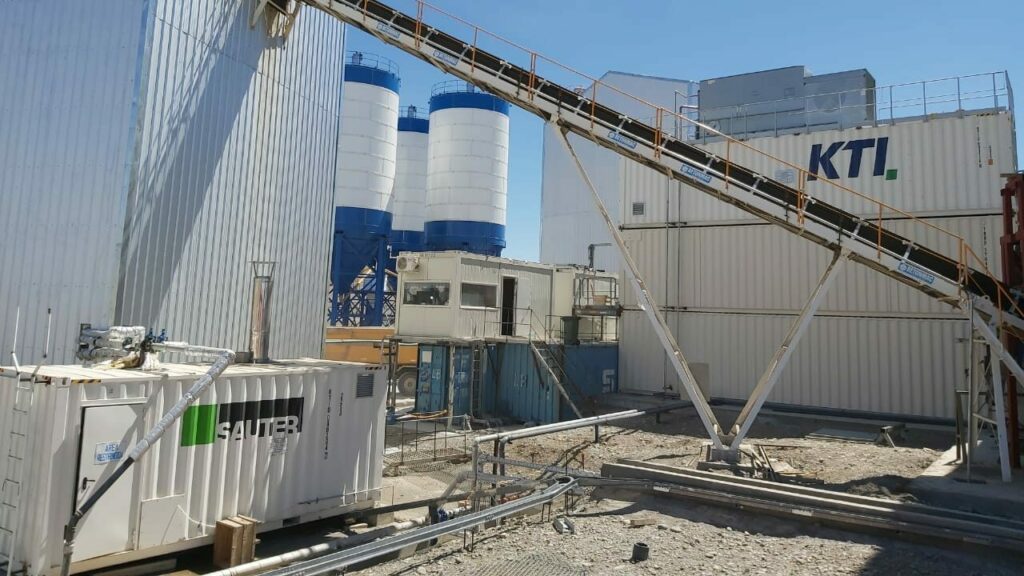

KTI – ConTempCo

Our reference projects

Our equipment for concrete cooling and concrete heating is in use all over the world. We would like to share some selected examples to give you the best impression of our solutions.

>1000

~50

>2500

~100

20

~100

5

Concrete cooling and heating for Argentine dam

More info

Combined heating and cooling plant at Ready-mix concrete plant

More info

KTI – ConTempCo

We are here for you

Contact our experts

Concrete Cooling & Concrete Heating

How would you like to be contacted?