KTI – Plersch

KTI Ice Slurry Generator (SIP)

KTI slurry generators are used when fish or other foodstuffs need to be cooled very quickly. Also in process cooling, as ice slurry can be pumped through a network of pipes.

KTI ice slurry systems convert salt water or a brine solution into ice slurry by passing solid ice crystals in supercooled liquid. Thus, the ice slurry is typically a mixture of ice crystals within a liquid phase such as brine, salt water or even other food liquids. The temperature of the ice slurry is about -3 °C.

KTI ice slurry systems convert salt water or a brine solution into ice slurry by passing solid ice crystals in supercooled liquid. Thus, the ice slurry is typically a mixture of ice crystals within a liquid phase such as brine, salt water or even other food liquids. The temperature of the ice slurry is about -3 °C.

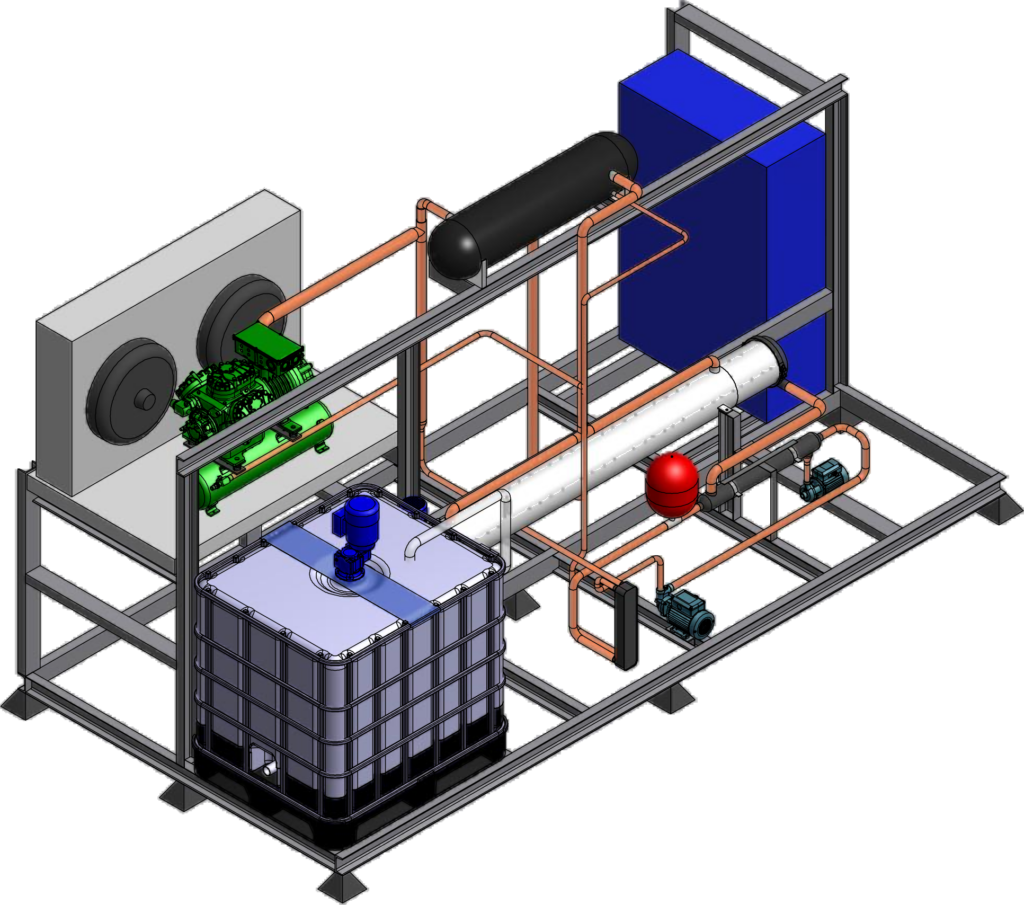

Compact plant for the production of ice slurry installed on frame. Two tanks for the provision of the brine are included.

KTI Ice Slurry Generator (SIP)

Plant information

KTI ice slurry generators are equipped with a heat exchanger which contains a rotating scraper inside and constantly removes the water freezing at the edge. The speed of the scraper thereby determines the ice particle sizewhile the flow rate of the brine or saline water is the ice-water ratio is predefined. This allows the mass fraction of solid ice particles to be adjusted. The fewer ice particles the ice slurry contains, the easier it is to pump, but it also contains less "cooling energy".

Another way to produce ice slurry is to, water and solid ice in a special tank with agitator to mix. This method is ideally used if a KTI flake ice plant or KTI plate ice machine is already available.

KTI Ice Slurry Generator (SIP)

The most important details at a glance

-3

°C Ice slurry

20 / 40

Foot ISO container

KTI Ice Slurry Generator (SIP)

Your advantages of KTI ice slurry generators

- KTI ice slurry generators produce ice slurry very energy-efficient.

- KTI ice slurry generators produce ice slurry with temperatures from -3 °C.

- KTI ice slurry generators offer the highest cooling rate and fastest temperature drop.

- KTI ice slurry generators are also extremely compact for large outputs.

- KTI ice slurry generators are an ideal addition to your existing ice plant.

KTI Ice Slurry Generator (SIP)

Ice slurry offers the highest cooling rates

The biggest advantage of ice slurry is the highest cooling rate compared to flake ice or plate ice. Due to the High flowability of ice slurry, it covers the entire product and penetrates very quickly into small openings. However, ice slurry has a lower specific energy compared to conventional solid ice. This means that more ice slurry is needed to achieve the same temperature reduction. When it comes to the cooling of food, the high speed of cooling always plays an overriding role.

Expert knowledge

Our KTI ice slurry plants are used in particular in the fishing industry. Here, the use of ice slurry has played a major role for many years for the rapid cooling of the catch. The faster fish is cooled, the longer its shelf life!

However, because ice slurry can be pumped, its applications are far more diverse. For example, the capacity in an existing cooling network can be expanded without significantly changing the piping. This could also play a role in providing district cooling in the future.

However, because ice slurry can be pumped, its applications are far more diverse. For example, the capacity in an existing cooling network can be expanded without significantly changing the piping. This could also play a role in providing district cooling in the future.

KTI Ice Slurry Generator (SIP)

Other ice plants

KTI – Plersch

We are here for you

Your contact to our experts

How would you like to be contacted?